ADDITIONAL SERVICES

Fuel Testing

When diesel is bulk stored without treatment for longer than 6-12 months  it can become contaminated. Dirty fuel ultimately is a threat to your critical systems, loss of standby power, business continuity and could cost thousands in damage if left untreated.

it can become contaminated. Dirty fuel ultimately is a threat to your critical systems, loss of standby power, business continuity and could cost thousands in damage if left untreated.

Contaminants in your stored fuel are incredibly harmful to emergency generators and their ageing infrastructures as it can damage clog filters, fuel injectors and if your tank has layers of build-up it can cause detrimental oil spills from tank/pipe failure and overfills. Our inhouse sampling and testing service analyses the water, particulate and chemicals, checking the quality of your stored fuel and determines the next steps which could include: fuel cleaning, fuel uplifting or a new supply.

Fuel Polishing

If your fuel sample and testing highlights your fuel is out of specification as it contains high levels of suspended water or particulate contamination, we can clean, filter and polish your stored fuel back to Class A2 Refinery grade specification for both water and particulate.

In general terms, more than 90% of contamination can be found in the bottom 10% of the tank! We have a range of specialist probes, pipes and pumps that draw up this section of the tank enabling us to filter your fuel more effectively.

In general terms, more than 90% of contamination can be found in the bottom 10% of the tank! We have a range of specialist probes, pipes and pumps that draw up this section of the tank enabling us to filter your fuel more effectively.

Our systems are capable of processing more than 100,000 litres in a single day! We have a range of fuel cleaning platforms, giving us options for any project whatever the size and nature of the fuel to be cleaned.

Once the contaminated fuel is removed, we will provide a full report and waste certification, under the terms of our EA (Environment Agency) waste permit licence for evidence that your fuel is maintained by specialists and you’ll have ‘peace of mind’ it’s reliable.

There are many reasons to consider why your stored fuel needed filtering, polishing and cleaning. It could just be part of your regular proactive maintenance plan, or it could be because of a wider issue that your tank and its infrastructure needs testing and cleaning which is why you’ve experienced fuel that’s out of specification.

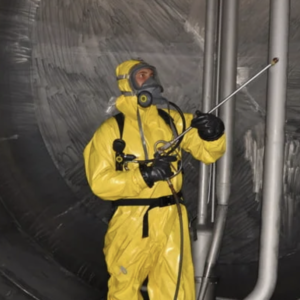

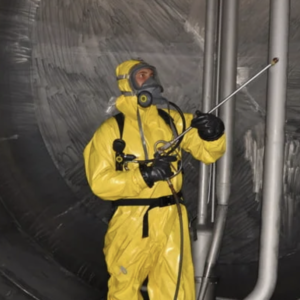

Industrial Tank Cleaning

Industrial tank cleaning is a crucial process in various sectors such as manufacturing, petrochemicals, food processing, and wastewater treatment. It involves the removal of residue, contaminants, and other unwanted materials from tanks, vessels, and other storage containers used in industrial processes.

Keeping your tanks clean, protects from contamination and degradation  for both your fuel and your tank.

for both your fuel and your tank.

- A tank clean is recommended to ensure compliance and avoids pollution incidents, mandatory fines and emergency spill costs. Our confined spaces operatives are highly trained and experienced in working in high-risk environments.

- Where non-many entry systems are not practical, strict health and safety systems are adhered to.

- Once the fuel has been uplifted, we will remove contaminants from the bottom of the tank using specialist hoses connected to a vacuum tanker.

Finally, the tank is jet washed, dried and inspected by our specialist team. Proper planning, adherence to safety protocols, and the use of appropriate cleaning methods are essential for successful tank cleaning operations.

NDT Tank Testing

NDT testing is “non-destructive testing” and is the application of  measurement techniques in order to identify damage and irregularities in the material of the tank. It’s vital, as NDT is seen as the only method of being able to see the current ‘health’ of a tank.

measurement techniques in order to identify damage and irregularities in the material of the tank. It’s vital, as NDT is seen as the only method of being able to see the current ‘health’ of a tank.

NDT tests include a range of different tests and services and are dependent upon your unique requirements. Tests may include:

- Tank thickness testing

- Tank base testing

- Tank weld testing

- Hardness testing

- Ultrasonic inspection

- UAV inspection

Industrial Tank Installation

Our skilled workforce, are trained to the standards required by OCTEL, HSE and MOD SRP3. We have a wealth of experience in fuel tank and pipe installations. Whether you are implementing a one-off project or you’re installing a new tank as it’s part of a full site decommissioning, we understand and can meet the unique needs and demands of our clients across the UK.

We can install and commission both metal and plastic tanks for:

- Red diesel (gas oil)

- White diesel (derv)

- Kerosene

- HFO (heavy fuel oil)

- Waste oil

- Water

- Solvents and etc

Industrial Tank Decommissioning

We can compliantly decommission tank storage facilities up to and including COMAH registered infrastructure, above ground or below ground tank (or many tanks). Tank cutting, tank removal and any subsequent civil works.

Your fuel tank may need decommissioning if it is out of warranty, you’ve  recently discovered buried tank, a complex pipework system, damaged infrastructure, failed a specific tank test or is registered as too much of a risk by a client (typically both environmentally and commercially) our team are able to help.

recently discovered buried tank, a complex pipework system, damaged infrastructure, failed a specific tank test or is registered as too much of a risk by a client (typically both environmentally and commercially) our team are able to help.

We have a rich history of delivering tank decommissioning projects to large public sector clients. As a commercial services supplier, we have successfully supported public sector clients in utilising the most recent available frameworks.

Emptying and Cleaning of Fuel and Oil Interceptors

In industrial/factory sites, refuelling areas etc.

In industrial/factory sites, refuelling areas etc.

All types such as:

- Full retention interceptors

- Bypass interceptors

it can become contaminated. Dirty fuel ultimately is a threat to your critical systems, loss of standby power, business continuity and could cost thousands in damage if left untreated.

it can become contaminated. Dirty fuel ultimately is a threat to your critical systems, loss of standby power, business continuity and could cost thousands in damage if left untreated. In general terms, more than 90% of contamination can be found in the bottom 10% of the tank! We have a range of specialist probes, pipes and pumps that draw up this section of the tank enabling us to filter your fuel more effectively.

In general terms, more than 90% of contamination can be found in the bottom 10% of the tank! We have a range of specialist probes, pipes and pumps that draw up this section of the tank enabling us to filter your fuel more effectively. for both your fuel and your tank.

for both your fuel and your tank. measurement techniques in order to identify damage and irregularities in the material of the tank. It’s vital, as NDT is seen as the only method of being able to see the current ‘health’ of a tank.

measurement techniques in order to identify damage and irregularities in the material of the tank. It’s vital, as NDT is seen as the only method of being able to see the current ‘health’ of a tank.

recently discovered buried tank, a complex pipework system, damaged infrastructure, failed a specific tank test or is registered as too much of a risk by a client (typically both environmentally and commercially) our team are able to help.

recently discovered buried tank, a complex pipework system, damaged infrastructure, failed a specific tank test or is registered as too much of a risk by a client (typically both environmentally and commercially) our team are able to help.